Jr Products

Jr Products Double Rv Rocker Switch Assembly With Bezel - 12145 - 342-12145F1

Ratings: SPST, 16 Amp @ 125-250 VAC, 3/4 H.P @ 125-250 VAC, 10 Amp @ 14V (T)UL/CSA/VDE approvedCutout Dimensions:Single: 1.625" x 1.25" Double: 1.625" x 2.437"Triple: 1.625" x 3.625" Quad: 1.625" x 4.813"

Jr Products Double Rv Rocker Switch Assembly With Bezel - 12235 - 342-12235F1

Ratings: SPST, 16 Amp @ 125-250 VAC, 3/4 H.P @ 125-250 VAC, 10 Amp @ 14V (T)UL/CSA/VDE approvedCutout Dimensions:Single: 1.625" x 1.25" Double: 1.625" x 2.437"Triple: 1.625" x 3.625" Quad: 1.625" x 4.813"

Jr Products Drawer Slide Repair Kit - 70985 - 342-70985F1

Universal replacement drawer slide kit contains all of the plastic replacement parts needed to repair a sliding cabinet or desk drawer. Includes mounting screws. Lifetime warranty.

Jr Products Drawer Slide Socket Set C" Shape - 70725 - 342-70725F1

This drawer socket can be identified by looking at its opening where it resembles a larger "C" shape. It is an adjustable socket for a universal application. Includes mounting screws. Lifetime warranty.

Jr Products Drawer Slide Socket Set C" Shape - 70735 - 342-70735F1

This drawer socket can be identified by looking at its opening where it resembles a larger "C" shape. It is an adjustable socket for a universal application. Includes mounting screws. Lifetime warranty.

Jr Products Dust Plug For City Water Check Valve - 62105 - 342-62105F1

Universal, fits most city water fills Constructed of flexible 100% rubberFits Part #62115, 62125, 62135, 62145, 62155, 62165, 62175, 62185

Jr Products Efps130 Replacement Gas Spring End Fitting W/Snap-On Cap - Ef-Ps130 - 342-Efps130F1

Lifetime warranty.

Jr Products Efps30 Replacement Gas Spring End Fitting W/Steel Spring - Ef-Ps30 - 342-Efps30F1

Lifetime warranty.

Jr Products Efps90A Replacement Gas Spring Angled End Fitting - Ef-Ps90A - 342-Efps90Af1

Lifetime warranty.

Jr Products Elastic Sew-In Curtain Carrier - 81275 - 342-81275F1

Type C Curtain Carrier. Lifetime warranty.

Jr Products End Mount Trigger Latch For Rv Compartment Door - 10935 - 342-10935F1

High quality steel provides both security and durability. Replacement for any latch of the same configuration and basic size. Most commonly connected to a center mount operator assembly, using specially designed rods or with universal adjustable cables. Lifetime warranty.

Jr Products End Mount Trigger Latch For Rv Compartment Door - 10945 - 342-10945F1

High quality steel provides both security and durability. Replacement for any latch of the same configuration and basic size. Most commonly connected to a center mount operator assembly, using specially designed rods or with universal adjustable cables. Lifetime warranty.

Jr Products End Stop - Type D - 81385 - 342-81385F1

For use with track Type "D". Lifetime warranty.

Jr Products Exterior Tv Jack - 47755 - 342-47755F1

This unit comes with a 75 ohm F-Style connector and a flip-up door that stays open for easier access. It is constructed of durable polypropylene for a long life. Cutout Dim: 0.500" x 0.500"Outside Dim: 2.062" x 2.062"

Jr Products Fabric-To-Fabric Snap Kit, 6/Pk - 81575 - 342-81575F1

These units are used to add a snap attachment to any fabrics such as tarps, awning material or curtains. Use part #81565 tool kit to install. Lifetime warranty.

Jr Products Fabric-To-Wall Snap Kit, 6/Pk - 81585 - 342-81585F1

These units are used to add a snap attachment to any fabric or material where they are fastened to a wall or solid structure such as screen rooms, interior curtains, or security straps. Use Part #81565 tool kit to install. Lifetime warranty.

Jr Products Female Flare To Mpt Connector - 07-30225 - 342-0730225F1

3/8" Female Flare to 1/4" MPT Used to connect two LP Hoses or fittingsNot for potable water use (contains lead)

Jr Products Folding Shelf Bracket, White - 20725 - 342-20725F1

Sturdy support for any type of fold down shelf Supports up to 50 lbs.Lifetime warranty

Jr Products Free Swing Flush Mount Hinge, Satin Nickel - 70655 - 342-70655F1

Free swing cabinet door hinges are universal replacements for any flush mount application. Includes mounting screws. Lifetime warranty.

Jr Products Fx2K Pressurepro Fx Tpms, 2 Wheel Kit - Fx2K - 342-Fx2Kf1

The first TPMS designed specifically for towables, PULSE FX delivers PressurePro's first BYOD based system, arming users with market leading tire performance management at never-before-seen value. Allowing users to leverage existing smart devices to display real time readings and alerts directly through the free, PressurePro app, FX gives users: 24/7 tire performance monitoringFive unique alerts including Tire Pressure and Tire TemperaturePush notifications and FX warning lightUnit is sealed, and can be fully submerged in waterAbility to monitor up to 40 tiresVehicle naming and storage for easy monitoring of multiple trailersFully adjustable vehicle layout and displayFully customizable baseline and alerts KIT INCLUDES:PULSE FX DeviceDynamic Standard SensorsPULSE Fixed End Power CablePULSE Dipole AntennaFX Hook & Loop Mounting Pads

Jr Products Fx4K Pressurepro Fx Tpms, 4 Wheel Kit - Fx4K - 342-Fx4Kf1

The first TPMS designed specifically for towables, PULSE FX delivers PressurePro's first BYOD based system, arming users with market leading tire performance management at never-before-seen value. Allowing users to leverage existing smart devices to display real time readings and alerts directly through the free, PressurePro app, FX gives users: 24/7 tire performance monitoringFive unique alerts including Tire Pressure and Tire TemperaturePush notifications and FX warning lightUnit is sealed, and can be fully submerged in waterAbility to monitor up to 40 tiresVehicle naming and storage for easy monitoring of multiple trailersFully adjustable vehicle layout and displayFully customizable baseline and alerts KIT INCLUDES:PULSE FX DeviceDynamic Standard SensorsPULSE Fixed End Power CablePULSE Dipole AntennaFX Hook & Loop Mounting Pads

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-2125-90 - 342-Gsni212590F1

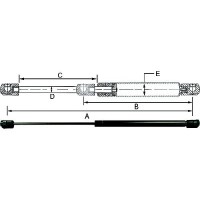

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-2200-90 - 342-Gsni220090F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-2300-100 - 342-Gsni2300100F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-2300-120 - 342-Gsni2300120F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-2300-150 - 342-Gsni2300150F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-2300-80 - 342-Gsni230080F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-2300-90 - 342-Gsni230090F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-2600-100 - 342-Gsni2600100F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-4032-28 - 342-Gsni403228F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-4033-30 - 342-Gsni403330F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-4688-40 - 342-Gsni468840F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-4983-35 - 342-Gsni498335F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-4991-60 - 342-Gsni499160F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-5000-20 - 342-Gsni500020F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-5000-60 - 342-Gsni500060F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-5100-30 - 342-Gsni510030F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-5100-40 - 342-Gsni510040F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.GNSI-5100-40 is used on truck caps.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-5150-20 - 342-Gsni515020F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-5150-40 - 342-Gsni515040F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-5150-60 - 342-Gsni515060F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-5200-30 - 342-Gsni520030F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-5200-40 - 342-Gsni520040F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-5200-50 - 342-Gsni520050F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.GSN5200-50 is used on truck caps.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-5200-60 - 342-Gsni520060F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-5300-10 - 342-Gsni530010F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-5300-20 - 342-Gsni530020F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-5300-30 - 342-Gsni530030F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-5300-40 - 342-Gsni530040F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-5300-50 - 342-Gsni530050F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-5300-60 - 342-Gsni530060F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-6624 - 342-Gsni6624F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-6642 - 342-Gsni6642F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.GSNI-6642 is used on truck caps.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-6687 - 342-Gsni6687F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-7145 - 342-Gsni7145F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Hardline Black Nitride Shaft Gas Spring - Gsni-7903 - 342-Gsni7903F1

Combines all the proven reliability you've come to expect from an SPD Gas Spring along with the added feature of a nitride shaft. The GSNI Gas Spring incorporates a strong annealed steel rod with a Nitride coating for added corrosion resistance, especially when used with the all composite PS130 end fitting. This gas spring is an ideal choice where exceptional quality, combined with an overall black appearance, are important for your application. GAS SPRING FIT AND SELECTIONIf you already have a gas spring installed, selecting a replacement can be as simple as A-B-C. A. Measure the extended length from center mounting hole to center mounting hole (see "A" in diagram). B. Measure the amount of piston that is exposed while extended. This is called the stroke of the gas spring. (see "C" in diagram). C. Find the extended length that is the closest to your current unit. Then use either the stroke measurement or subtract the stroke from extended and select the compressed sizes that are closest to your current spring.(The measurements do not have to be exact but the closer you can match the original the easier it will be to install.) SELECTING THE FORCE - If your current spring has a stamped label, the force should be listed within that number. Usually, the last two digits or followed by the letter N which is Newtons. One pound equals 4.4482 Newtons. This is the pounds of force being exerted to open or hold open the door or platform. It does not equal the weight of the item being lifted. Trial and error is not the best way to find that number.

Jr Products Heavy Duty On/Off/Momentary-On Rv Switch - 12825 - 342-12825F1

Ratings: DPDT, 20 Amp @ 125 VAC, 15 Amp @ 250 VAC, 40 Amp @ 12 VDCUL/CSA/VDE approvedCutout: 1.25" x .84"Switch: 2.75" x 1.80"

Jr Products Heavy Duty On/Off/Momentary-On Rv Switch - 12835 - 342-12835F1

Ratings: DPDT, 20 Amp @ 125 VAC, 15 Amp @ 250 VAC, 40 Amp @ 12 VDCUL/CSA/VDE approvedCutout: 1.25" x .84"Switch: 2.75" x 1.80"

Jr Products Hitch Pin/Hitch Pin Clip Combo - 1065 - 342-01065F1

A replacement combination of our high quality hitch pin and hitch pin clip. Constructed of durable chromatic plated steel. Never guess if your clip or pins will fit each other, simply buy a matched set.

Jr Products Hitch Pin/Hitch Pin Clip Combo - 1074 - 342-01074F1

A replacement combination of our high quality hitch pin and hitch pin clip. Constructed of durable chromatic plated steel. Never guess if your clip or pins will fit each other, simply buy a matched set.

Jr Products Hitch Pin/Hitch Pin Clip Combo - 1144 - 342-01144F1

A replacement combination of our high quality hitch pin and hitch pin clip. Constructed of durable chromatic plated steel. Never guess if your clip or pins will fit each other, simply buy a matched set.

Jr Products Hth-A Dual Voltage Rv Holding Tank Heater - Hth-A - 342-Hthaf1

Use on either fresh water or septic tank Dual voltage ready for 12V and 110V applicationsThermostatically controlled and active at 34° F24" ground wireDraws approximately 1 Amp AC and 10 Amps DCMultiple heaters may be used where needed

Jr Products Inside L-Handle - 10905 - 342-10905F1

This unit is used on the interior of popular T and L locking handles. It provides the ability to open the doors from inside the truck cap or compartment. Fits most square-shaft operating handles. Lifetime warranty.

Jr Products Interior Cable Tv Plate - 47785 - 342-47785F1

Interior Cable TV Plate has a 75 ohm F-Style connection. Works for any F-Style TV or satellite installations. Can be used in HD/Satellite TV connections. 2.34" x 4.50"

Jr Products Kappet Screws With Covers, Beige, 14/Pk - 20425 - 342-20425F1

Can be used any where you need to secure an item with a screw but desire a clean, finished look. Special mounting screws included. Lifetime warranty.

Jr Products Kappet Screws With Covers, White, 14/Pk - 20415 - 342-20415F1

Can be used any where you need to secure an item with a screw but desire a clean, finished look. Special mounting screws included. Lifetime warranty.

Jr Products Labeled 12V 5 Pack Rv On/Off Switches - 12581-5 - 342-125815F1

Ratings: SPST, 16 Amps @125 VAC, 12 Amp @ 250 VAC, 3/4H.P. @ 125-250 VAC, 10 Amps @ 14VDCUL/CSA/VDE/RoHS approvedCutout: 1.125" x .550"Switch: 1.120" x .547"

Jr Products Labeled 12V 5 Pack Rv On/Off Switches - 12591-5 - 342-125915F1

Ratings: SPST, 16 Amps @125 VAC, 12 Amp @ 250 VAC, 3/4H.P. @ 125-250 VAC, 10 Amps @ 14VDCUL/CSA/VDE/RoHS approvedCutout: 1.125" x .550"Switch: 1.120" x .547"

Jr Products Labeled 12V 5 Pack Rv On/Off Switches - 12611-5 - 342-126115F1

Ratings: SPST, 16 Amps @125 VAC, 12 Amp @ 250 VAC, 3/4H.P. @ 125-250 VAC, 10 Amps @ 14VDCUL/CSA/VDE/RoHS approvedCutout: 1.125" x .550"Switch: 1.120" x .547"

Jr Products Labeled 12V On/Off Switch, Black - 12595 - 342-12595F1

Ratings: SPST, 16 Amps @125 VAC, 12 Amp @ 250 VAC, 3/4H.P. @ 125-250 VAC, 10 Amps @ 14VDCUL/CSA/VDE/RoHS approvedCutout: 1.125" x .550"Switch: 1.120" x .547"

Jr Products Labeled 12V On/Off Switch, Black - 12615 - 342-12615F1

Ratings: SPST, 16 Amps @125 VAC, 12 Amp @ 250 VAC, 3/4H.P. @ 125-250 VAC, 10 Amps @ 14VDCUL/CSA/VDE/RoHS approvedCutout: 1.125" x .550"Switch: 1.120" x .547"

Jr Products Labeled 12V On/Off Switch, Brown - 12605 - 342-12605F1

Ratings: SPST, 16 Amps @125 VAC, 12 Amp @ 250 VAC, 3/4H.P. @ 125-250 VAC, 10 Amps @ 14VDCUL/CSA/VDE/RoHS approvedCutout: 1.125" x .550"Switch: 1.120" x .547"

Jr Products Labeled 12V On/Off Switch, White - 12585 - 342-12585F1

Ratings: SPST, 16 Amps @125 VAC, 12 Amp @ 250 VAC, 3/4H.P. @ 125-250 VAC, 10 Amps @ 14VDCUL/CSA/VDE/RoHS approvedCutout: 1.125" x .550"Switch: 1.120" x .547"

Jr Products Large Rv Kitchen Sink Strainer - 95285 - 342-95285F1

Fits any sink opening 3-1/2" - 4" Constructed of plastic or stainless steelIncludes: strainer, rubber washer and lock nut

Jr Products Large Rv Kitchen Sink Strainer - 95295 - 342-95295F1

Fits any sink opening 3-1/2" - 4" Constructed of plastic or stainless steelIncludes: strainer, rubber washer and lock nut

Jr Products Large Sliding Eye Curtain Carrier, Type A - 81085 - 342-81085F1

Lifetime warranty.

Jr Products Large Window Latch - 81875 - 342-81875F1

Replaces most top mounted groove strike latches 2.25" mounting patternMounting screws includedLifetime warranty

Jr Products Low Pressure 2-Stage 195,000 Btu/Hr Lp Rv Gas Regulator - 07-30365 - 342-0730365F1

Ideally designed for RV applications, these regulators ensure a smooth and continuous flow of gas to all appliances. Combines both a high pressure first stage and a low pressure second stage regulator into one unit. Zinc Die CastMolded Rubber DiaphragmsUL Approved2nd Stage Relief Mechanism Per UL 144Adjustable Screw and Dust Cap DesignPowder Coated

Jr Products Low Pressure 2-Stage 195,000 Btu/Hr Lp Rv Gas Regulator - 07-30385 - 342-0730385F1

Ideally designed for RV applications, these regulators ensure a smooth and continuous flow of gas to all appliances. Combines both a high pressure first stage and a low pressure second stage regulator into one unit. Zinc Die CastMolded Rubber DiaphragmsUL Approved2nd Stage Relief Mechanism Per UL 144Adjustable Screw and Dust Cap DesignPowder Coated

Jr Products Low Pressure 2-Stage Automatic Changeover Regulator - 07-31525 - 342-0731525F1

Compact version Automatically redirects LP gas vapor flow from an empty designated service cylinder to a reserve cylinder without interruptionGreen indicator dome changes to red when the service cylinder needs to be filled1/4" Inverted Flare Inlet Connections3/8" FPT Outlet ConnectionZinc Die CastMolded Rubber DiaphragmsUL Approved2nd Stage Relief Mechanism Per UL 144Powder Coated

Jr Products Low Profile Bumper Door Holder - 10665 - 342-10665F1

Polymer plastic stem and rubber socket Will not fadeMounting screws includedLifetime warranty

Jr Products Low Profile Rv Slide Out Switch With Bezel - 12345 - 342-12345F1

Mom-On/Off/Mom-OnUse with wiring harness #13061Preprinted slide room plate12 V 40 Amp continuousCutout: 1.67" x 0.95"Switch: 2.87" x 1.87"White

Jr Products Low Profile Rv Slide Out Switch With Bezel - 12355 - 342-12355F1

Mom-On/Off/Mom-OnUse with wiring harness #13061Preprinted slide room plate12 V 40 Amp continuousCutout: 1.67" x 0.95"Switch: 2.87" x 1.87"Black

Jr Products Metal Floor Registers, Brown Dampered - 02-28915 - 342-0228915F1

Constructed of durable steel Long lasting powder coated colorsOEM replacement sizesEasy, one hand damper operationScrew hole for secure installation

Jr Products Metal Floor Registers, Brown Dampered - 02-28975 - 342-0228975F1

Constructed of durable steel Long lasting powder coated colorsOEM replacement sizesEasy, one hand damper operationScrew hole for secure installation

Jr Products Metal Floor Registers, Brown Undampered - 02-28955 - 342-0228955F1

Constructed of durable steel Long lasting powder coated colorsOEM replacement sizesEasy, one hand damper operationScrew hole for secure installationUndampered version has an extra collar depth for better air control

Jr Products Metal Floor Registers, Brown Undampered - 02-28995 - 342-0228995F1

Constructed of durable steel Long lasting powder coated colorsOEM replacement sizesEasy, one hand damper operationScrew hole for secure installationUndampered version has an extra collar depth for better air control

Jr Products Metal Floor Registers, White Dampered - 02-28905 - 342-0228905F1

Constructed of durable steel Long lasting powder coated colorsOEM replacement sizesEasy, one hand damper operationScrew hole for secure installation

Jr Products Metal Floor Registers, White Undampered - 02-28925 - 342-0228925F1

Constructed of durable steel Long lasting powder coated colorsOEM replacement sizesEasy, one hand damper operationScrew hole for secure installationUndampered version has an extra collar depth for better air control

Jr Products Metal Floor Registers, White Undampered - 02-28945 - 342-0228945F1

Constructed of durable steel Long lasting powder coated colorsOEM replacement sizesEasy, one hand damper operationScrew hole for secure installationUndampered version has an extra collar depth for better air control

Jr Products Metal T-Style Door Holder, 4" - 10495 - 342-10495F1

Constructed of zinc plated steel Replaces any T-Style door holderMounting screws includedLifetime warranty

Jr Products Metal T-Style Door Holder, 6" - 10505 - 342-10505F1

Constructed of zinc plated steel Replaces any T-Style door holderMounting screws includedLifetime warranty

Jr Products Metal Vent Crank - 20305 - 342-20305F1

Replacement Metal Vent Crank will fit most applications. Made of die cast steel for long lasting use and comes with a replacement screw. Lifetime warranty.

Jr Products Mini 12V On/Off Switches, Black/Black - 12785 - 342-12785F1

SPST, 16 Amp @ 125 VAC, 16 Amp @ 250 VAC, 3/4 H.P. @ 125-250 VAC, 10 Amp @ 14 VDCUL/CSA/VDE approvedCutout: 0.756" x 0.508"Switch: 0.745" x 0.500"

Jr Products Mini Blind Brackets - 81915 - 342-81915F1

Snap shut front for easier use ID 1"H x 1"WMounting screws includedLifetime warranty

Jr Products Mini Illuminated On/Off Switches - 120V, Spst - 12765 - 342-12765F1

Illuminates when switch is in the "on" positionSPST, 10 Amps @ 125 VAC, 6 Amps @ 250 VAC, 15 Amps @ 12 VDCUL/CSA/VDE approvedCutout: 0.745" x 0.500"Switch: 0.756" x 0.508"

Jr Products Mini Labeled On/Off Switch - 13735 - 342-13735F1

DPST, 20 Amp @ 125 VAC, 15 Amp @ 250 VAC, 40 Amp Peak/20 Amp continuous @ 12 VDCUL/CUL/RoHS approvedCutout: 0.756" x 0.508"Switch: 0.745" x 0.500"

Jr Products Mini Mom-On/Off Switch - 12815 - 342-12815F1

Ratings: SPST, 13 Amps @125 VAC, 10 Amps @ 250 VAC, 1/2 H.P. @ 125-250 VAC, 5 Amps @ 14 VDCUL/CSA/RoHS approvedCutout: 0.745" x 0.500"Switch: 0.756" x 0.508"